5.17.2012 – Thursday

I like lists. They convey complex information in an organized fashion (when correctly constructed). I’ve been reading through some old posts on the blog and realized I have a lot of information spread out over roughly 50 posts. Since I usually write a post at a milestone moment or when I learn something really cool my thoughts can get a little scattered. That’s why I created the “Posts menu” at the right and listed posts categorically – I’ve even tried to keep some congruity in how I title them. In the spirit of organization I’ve going to attempt to summarize some of the information that I think is fundamental to proper battery management.

The focus of this post is on batteries, since this is pretty much the single item in a completed off-grid system that requires maintenance and attention. The solar panels may require an occasional cleaning but I would consider this out of the ordinary since rain does a pretty good job at cleaning off dust and other particulates. The inverter and wiring should perform without flaw if correctly installed. So… on to batteries and the top 10 things I’ve discovered through trial, error, research, and observation (with FLAs). It’s best to read the list in order.

- Charge Lag. I observed this phenomenon first hand on Jan 3, 2012 at 11:30am. After discharging the batteries to 53.5% (measured by specific gravity) a charge current of 102A was applied for ~72 minutes for a total of 123.3Ah of charger input. The batteries measured at 55.5% when they should have measured a theoretical 57.4%. The key to understanding charge lag is ‘equilibrium’ – it takes time for the SG* to become uniform throughout the battery. Also, note that the opposite effect will occur under heavy discharge (SG measurements will be falsely elevated for a short time after applying a heavy discharge current). Mixing the electrolyte with a bulb syringe specific gravity instrument will not correct a SG reading for charge lag.

- Temperature and Capacity. Everything moves slower in colder temperatures – all the way down to the molecular scale. Charge lag will become more pronounced because of this: slower molecular movement will slow the mixing of regions of high/low SG. The chemical reaction that transforms the stored chemical energy of a battery into electrical energy will slow down as well, and lead to a loss of functional battery capacity – at the cabin our 1540Ah summer capacity will drop to around 900Ah when its 25-30°F. An interesting thing to note is that if the batteries are used the temperature will rise (see #3).

- Internal Resistance. Just like mechanical friction (eg, rubbing cold hands together to generate heat) batteries have internal resistance – which also generates heat. If batteries were 100% efficient at converting chemical energy to electrical energy they would produce absolutely no heat (my laptop would also run cooler). This is also why battery chargers cannot operate at 100% efficiency: apply 10Ah to a battery and it may capture as little as 5Ah of that current and shed the remaining 5Ah as heat.

- Capacity will vary based on discharge current. Many factors will affect battery efficiency. Battery manufacturers acknowledge this and list discharge rates and use the following notation: C/4 = 4 hours to completely discharge a battery. A typical 220Ah FLA (Trojan T-105) has a C/2 = 145Ah, C/5 = 185Ah, C/20 = 220Ah, C/100 = 250Ah. Notice how capacity decreases with faster discharge rate. This is best understood because of greater internal resistance under heavy load (more energy lost as heat).

- Charge Efficiency changes with SOC. A battery with SOC <84% will readily accept a charge, in fact, it will accept roughly 91% of the charge current (only 9% is lost as heat). But when SOC >90% charge efficiency falls dramatically to <50% (over half of the charge current is lost as heat). The best way to try and understand this concept is to imagine setting a mouse trap or a larger jaw trap. Setting each requires that a spring be put under tension – the tension gradually increases, requiring more effort, until the trap is set. Just the same, a battery requires incrementally more energy to overcome resistance, as it approaches full charge. This is why it is best NEVER to use a generator for absorption or float charging! – it is resource intensive with little return. ALWAYS absorb or float charge with a renewable like solar.

- Sulfation (crystallization of lead sulfate). This term describes a chemical reaction occurring inside the battery at the plates. Lead sulfate forms under normal use and is reversed when the battery is charged shortly after discharging. Lead sulfate crystalizes and becomes permanent if the batteries are left in an undercharged state for an extended period of time (1+ months). It is best never to let a battery fall below 30%. It is a better rule to remain above 50% if possible. Charge current is a topic of interest when determining if the ratio of PV to battery is appropriate, or if there is adequate current to mix the electrolyte, but it is of no concern when worrying about sulfation. A fully charged battery is fully charged regardless of how long it takes. Regarding battery desulfators – don’t waste your money. The people who design and market this product lack a fundamental understanding of how radio-frequencies interact with matter; this product is most certainly a scam.

- 10°C / 18°F Rule. For every 10°C increase above 25-30°C (18°F above 77-86°F) battery life shortens by a factor of two – sulfation rate doubles. The opposite can reasonably be assumed for colder temperatures. This is why in winter I’m not overly concerned about the battery bank hovering around 85-95% SOC. Sulfation at 32°F is occuring at roughly 1/2 of 1/2 of 1/2 that as at standard temperature (8 times slower). However, it is still important to have a battery near full charge as often as possible, especially in warm weather.

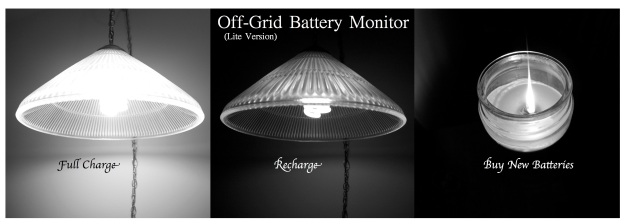

- Battery Monitors are awesome. If you have batteries, you should have a battery monitor. And when setting it, be conservative. On the Victron BMV-600s I initially set charge efficiency factor too high. Now I have it set at 74%. Strive for accuracy when setting it, but have a back-up method of assessing battery capacity. I created voltage/SOC charts as a way to double check the battery monitor. Writing down a specific point to recharge (as a back up) also works as a good double check. For example, at the cabin 11.9V, 300W AC load, 36°F battery temp. is about 60% SOC based on a specific gravity measurement.

- Don’t forget to water FLAs. With flooded lead acid batteries, maintenance is required to keep them in top form. I wouldn’t be surprised if good battery care effectively doubles the life-span of a battery bank. Use safe practices when maintaining batteries and follow manufacturer instructions on when to water and at what point in the charge cycle to add water. For most FLAs water is added after a full charge, unless plates are exposed prior to charging. I list my supplies and procedure for checking SG on the math :: SOC charts post. My preference is to then equalize after adding water to fully charged batteries – I do this once or twice each year.

- Take good notes and save useful information. I write everything down and keep several spreadsheets with data on the cabin system as well as every component manual and at least a dozen articles – all saved on my computer (and backed up). Keep a spreadsheet with key information on the battery bank. When recording information try and include date/time, specific gravity of each cell, voltage, current load (if applicable), and general observations/thoughts. It’s immensely helpful to have a baseline and provides a way to assess the performance over time.

I didn’t discuss battery equalization. There are many different approaches to this, from once a month to once a year. The rule of thumb is to perform this when SG differ by more than +/- .015 mg/ml between cells. Follow battery manufacturer instructions in this area.

*SG = specific gravity, SOC = state of charge; 0-100%

A quick question about the BMV-600 charge efficiency factory. Reading through the manual I got the impression that BMV calculates the CEF automatically. Is it a completely manual setting, an automatic setting or a semi-automatic setting where you set the initial value and BMV starts working from there?

I read the manual and arrived at the same conclusion (not sure what the BMV is doing). From use, I’m somewhat skeptical about the BMV-600 automatically calculating CEF in any capacity and I haven’t seen a noticeable difference from the value I manually entered.